There are numerous grades of high-temperature alloys, which can be classified into different categories based on their processing methods and strengthening mechanisms:

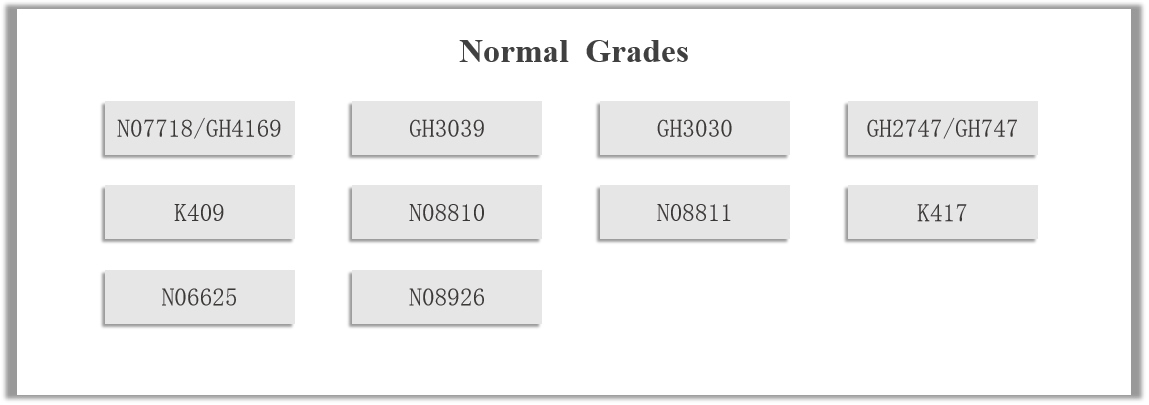

Wrought High-Temperature Alloys: Common wrought high-temperature alloy grades include GH4169, GH3039, etc.

Cast High-Temperature Alloys: Common cast high-temperature alloy grades include K409, K417, etc.

Powder Metallurgy High-Temperature Alloys: These alloys are produced through powder metallurgy processes and exhibit excellent mechanical properties and high-temperature stability. Common powder metallurgy high-temperature alloy grades include GH5188, GH3030, etc.

Dispersion-Strengthened High-Temperature Alloys: These alloys are strengthened by adding dispersed phases to enhance their high-temperature strength and oxidation resistance. Common dispersion-strengthened high-temperature alloy grades include GH2747, GH747, etc.

Fe-based High-Temperature Alloys: common Fe-Based high-temperature alloys include A-286, Alloy 800H/HT, etc.

Nickel-Based High-Temperature Alloys: Common nickel-based high-temperature alloy grades include Inconel 718, Inconel 625, etc.

Cobalt-Based High-Temperature Alloys: Cobalt-based high-temperature alloys exhibit good strength and corrosion resistance at high temperatures. Common cobalt-based high-temperature alloy grades include Haynes 188, Stellite 6B, etc.

Additionally, there are specialized high-temperature alloys for specific applications, such as Inconel 625 and Inconel 718 for high-temperature and high-pressure environments in oil extraction, and GH3039 and GH4169 for chemical equipment. When selecting an appropriate high-temperature alloy grade, factors such as operating temperature, stress conditions, and corrosive environment must be considered.

浙江双银特材科技有限公司组建于2020年3月,是一家整合了湖州南浔长银特材科技有限公司及湖州银环不锈钢有限公司的优势资源致力于特种材质的光亮管及精密管的生产加工企业。